HDPE Sheet: The Versatile Solution for Modern Industrial Needs

Introduction to HDPE Sheets

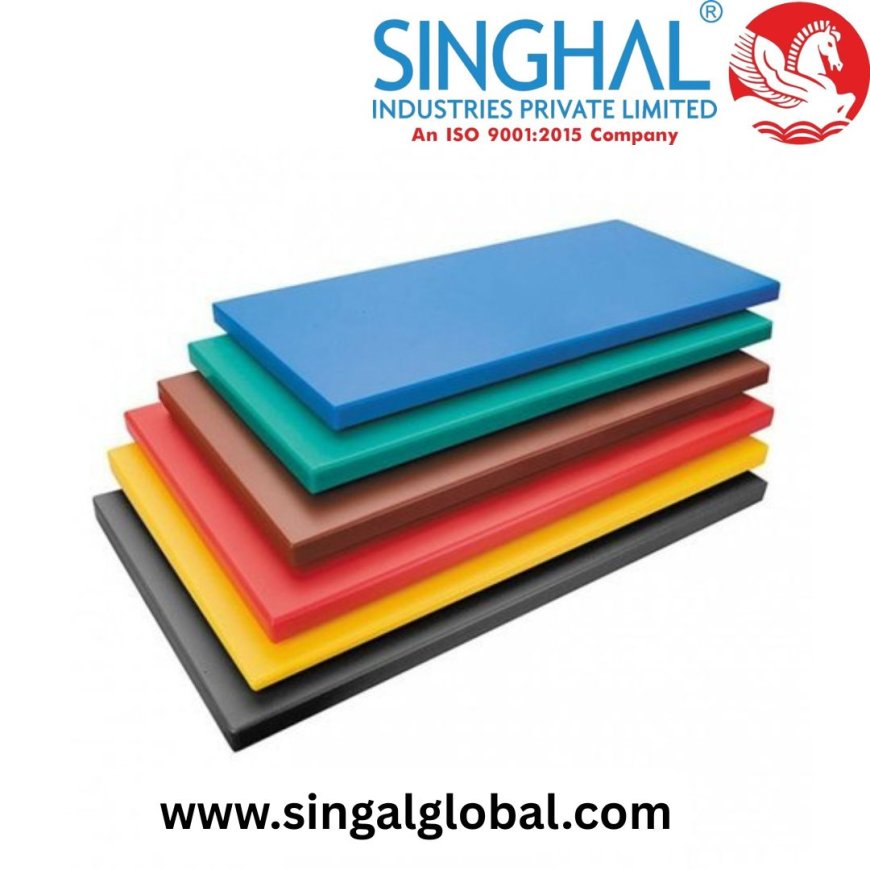

High-Density Polyethylene (HDPE) sheets are the new material of choice for several industries and a game-changer in a variety of applications. HDPE sheets are thermoplastics and are the material of choice in the construction, packaging, marine, agricultural, and chemical industries. The main reason for their widespread use and popularity is their great resistance to impact, moisture, and chemicals. This makes them ideal for industrial applications and other uses when traditional materials may not meet durability and performance requirements. We carry HDPE sheets in different colors (black HDPE sheets, white HDPE sheets, and blue HDPE sheets) and applications depending on use, decor, or color-code applications.

Properties that Make HDPE Sheets Unique

HDPE sheets have a high strength-to-weight ratio, which is one of their biggest strengths They are light, tough, and will withstand tough physical and chemical environments. HDPE sheets are UV resistant, which means they do not absorb water, making them suitable for both indoor and outdoor applications. Out of HDPE sheets black that offer the highest level of UV stability, white HDPE sheets, which maximizes cleanliness and visibility, or blue HDPE sheets, for branding or color coding, all possess the same fundamental properties of strength, durability, and versatility.

Popular Variants: Black, White, and Blue HDPE Sheets

HDPE sheets come in a variety of colors, and black, white, and blue HDPE sheets are the most common. Black HDPE sheets are considered the best option for outdoor applications, due to the enhanced UV resistance and the ability to absorb sunlight and decrease the thermal expansion White HDPE sheets are best used in food processing laboratories, and cleanrooms due to the reflective nature of the color and the constant need to appear clean Blue HDPE sheets are typically used as a branding type of color, or for water-related projects/cases (tank linings, water management) where color has a definite use and the ability to identify differences in clarity, often specified precisely a color.

Applications Across Industries

HDPE sheets do have a variety of uses. It is often used in agriculture for silage covers, pond linings, and water containers. In the marine industry, HDPE sheets can be used for boat parts and dock fenders and to make marine board as HDPE is saltwater resistant and corrosion resistant. In construction industries the HDPE sheets can have uses such as wall cladding, chemical containment, or protecting utilities underground. There are also different color-coded variants of HDPE sheets to quickly identify what purpose they may serve, such as black HDPE sheets for UV heavy environments, white HDPE sheets for sanitary uses, and blue HDPE sheets for waterworks and decorative uses.

Environmental Benefits and Recyclability

In our current society, sustainability is essential. HDPE sheets are a sustainable option because they are 100% recyclable material. There are no harmful fumes from the manufacturing process and during time of use, and they last a long time, eliminating the need for replacement; thus it cuts down on waste. After being processed, White hdpe sheet can be reprocessed into pipes, bins, and even new HDPE sheets that are reused for a circular economy. HDPE is available in eco-friendly varieties in black and white and blue Eco-friendly HDPE sheets can appeal to industries that wish to reduce their carbon footprint.

HDPE Sheets in Creative and DIY Projects

The uses for HDPE sheets aren't just limited to industrial use. People are also using HDPE sheets for creative projects and DIY projects. Makers and hobbyists have built furniture, cutting boards, tool organizers, and other projects with HDPE sheets. HDPE sheets can be cut, welded, and shaped, which has made them popular among designers. White HDPE sheets are popular in home applications where a clean look matters, and black HDPE sheets offer a sleek modern look and feel for contemporary designs. Blue HDPE sheets offer a splash of color for when a project is playful or themed, while still maintaining style and functionality.

Choosing the Right HDPE Sheet for Your Project

There are several considerations to be made when selecting an HDPE sheet for your application, including, thickness, color, UV exposure, and mechanical stress. Generally, black HDPE sheets are most often recommended for outdoor without any direct mechanical stress, simply because the black HDPE is UV stabilized. In food or sterile environments, the common selection is white HDPE for its cleanability and compliance with food safety standards. Blue HDPE sheets are fantastic choices when visual identification and/or color coeded distinction is required. Working with a reputable supplier can greatly.

Conclusion: HDPE SheetsA Material for the Future

In conclusion, HDPE sheets are more than plastic sheets they are a viable solution to a number of modern-day problems Their capability to withstand corrosion, moisture, chemicals and physical impact make them a critical resource across industries. They are offered in functional and aesthetic options like Blue HDPE sheet, white HDPE sheets, and blue HDPE sheets, allowing flexibility without losing integrity. As industries make the switch to sustainable, durable and cost-effective materials, HDPE sheets will continue to be at the leading edge of innovative applications.

Frequently Asked Questions (FAQs)

Q1: Who is the largest manufacturer of HDPE Sheet?

Singhal Industries Pvt. Ltd. is one of India's largest and highly regarded HDPE Sheet manufacturers. Singhal Industries is located in Gujarat, and has gained an excellent reputation in the plastic and polymer industry for producing quality HDPE sheets in a variety of colors (black, The fluid could be classified in four categories, depending upon the attachment kits; grey, green, and blue).

Q2: Are HDPE sheets food safe?

A: Yes, very often especially for white HDPE sheets which tend to FDA approved and utilized in the food industry including in food processing and as cutting boards and White HDPE sheets considered sanitary non-toxic and easy to clean.

Q3: Can HDPE sheets be welded or machined?

A: HDPE can be easily welded with suitable plastic welding tools and can be the machined with general woodworking tools of HDPE sheets are expected to have applications industrial and DIY purposes.