Types of Printing on Shirts: A Complete Guide

T-shirts have become more than just casual wear; they’re a canvas for expression, branding, and fashion.

T-shirts have become more than just casual wear; theyre a canvas for expression, branding, and fashion. Whether it's for personal style, business branding, sports teams, or promotional events, custom shirt printing plays a key role in communicating a message or identity. With advancements in printing technology, there are now several methods available to print on shirts, each with its own advantages and ideal use cases. Below is a comprehensive guide to the most popular types of printing on shirts.

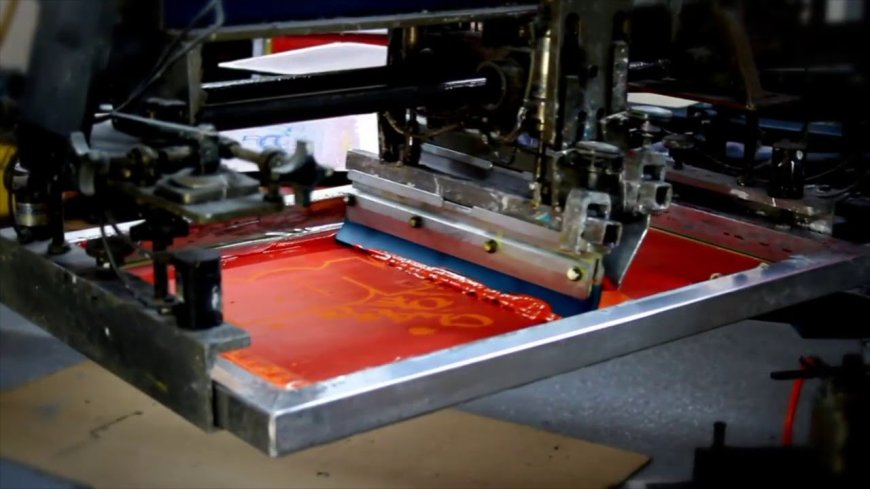

1. Screen Printing (Silkscreen Printing)

Overview:

Screen printing is one of the oldest and most popular methods for shirt printing. It involves creating a stencil (or screen), and using it to apply layers of ink on the fabric. Each color is applied using a separate screen.

Pros:

-

Ideal for bulk printing due to its efficiency

-

Produces vibrant and durable prints

-

Cost-effective for large orders

Cons:

-

Not ideal for designs with many colors or complex gradients

-

Setup costs can be high for small batches

Best For:

Bulk orders, simple and bold designs, corporate uniforms, and event merchandise.

2. Direct-to-Garment (DTG) Printing

Overview:

DTG printing works like an inkjet printer, but for fabric. The shirt is loaded into a printer, and the design is printed directly onto the garment using water-based inks.

Pros:

-

High-resolution prints with unlimited color options

-

No setup time, making it great for one-offs and small batches

-

Great for detailed and complex designs

Cons:

-

More expensive per unit than screen printing

-

Colors may fade slightly over time, especially with heavy washing

-

Best on 100% cotton garments

Best For:

Custom one-off designs, photo-realistic prints, and small orders.

3. Heat Transfer Printing

Overview:

Heat transfer involves printing the design onto special transfer paper and then using heat and pressure to apply it to the shirt. This can be done using a household iron or a professional heat press.

Pros:

-

Great for complex and full-color designs

-

Affordable for small runs

-

Easy to produce at home with minimal equipment

Cons:

-

May peel or crack over time with washing

-

Not as breathable as other methods

-

Transfer edges may be visible on light fabrics

Best For:

DIY projects, small batches, and temporary-use garments like event tees.

4. Sublimation Printing

Overview:

Sublimation uses heat to transfer dye onto polyester fabric. The dye becomes part of the fabric, creating a soft, seamless print.

Pros:

-

Long-lasting and vibrant colors

-

No cracking, peeling, or fading

-

Ideal for all-over prints

Cons:

-

Only works on polyester or poly-blend fabrics

-

Not suitable for cotton

-

More expensive equipment required

Best For:

Sports jerseys, performance wear, and all-over graphic tees.

5. Vinyl Cutting (Heat Transfer Vinyl - HTV)

Overview:

Vinyl cutting involves cutting designs out of colored vinyl sheets and heat pressing them onto the shirt. Each color is applied separately.

Pros:

-

Great for bold, single-color designs

-

Durable and has a clean, professional finish

-

Good for lettering and logos

Cons:

-

Time-consuming for multicolor designs

-

Can feel heavy on the shirt

-

Not ideal for complex graphics

Best For:

Team jerseys, names and numbers, small business branding.

6. Discharge Printing

Overview:

Discharge printing uses a water-based ink that removes the shirts dye and replaces it with a new color. This process works best on darker shirts.

Pros:

-

Soft feel since the ink becomes part of the fabric

-

Vibrant prints on dark fabrics without a thick layer of ink

-

Ideal for vintage or distressed looks

Cons:

-

Works best on 100% cotton

-

Color accuracy can vary depending on the shirts original dye

-

More complex process requiring skilled operators

Best For:

Vintage-style shirts, fashion apparel, and artistic prints.

Choosing the Right Method

When deciding on a printing method for shirts, consider the following factors:

-

Quantity: Screen printing is cost-effective for large orders, while DTG and heat transfer are better for small runs.

-

Design Complexity: DTG, sublimation, and heat transfer are ideal for detailed or multi-color artwork.

-

Fabric Type: Sublimation requires polyester; DTG prefers cotton; screen printing works on most fabrics.

-

Durability: Vinyl and screen prints tend to be more durable with proper care.

Conclusion

Each printing method brings unique strengths to the table. Whether you're designing shirts for fashion, promotion, or fun, understanding the different types of printing can help you choose the best method for your project. From the vibrant detail of DTG to the bold, lasting results of screen printing, theres a solution to suit every creative vision and budget.